Products

Optimized & Industry-ready Solutions

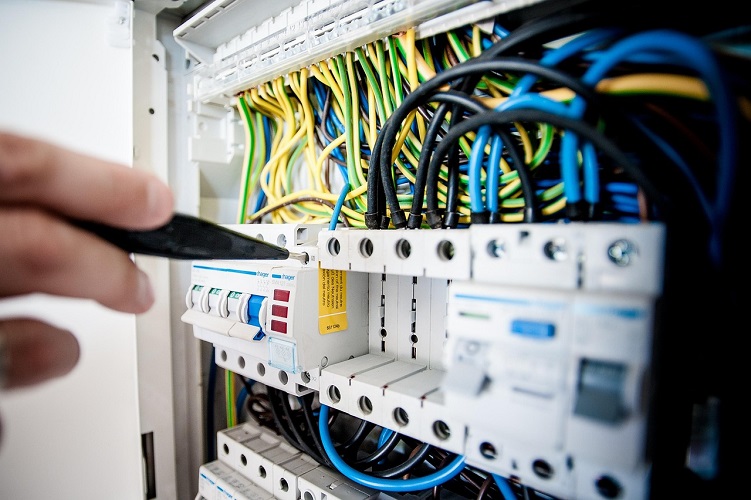

Control Panels for All Your Complicated Needs

As a leading control panel manufacturer, we specialize in designing and producing high-quality, reliable control solutions tailored for industrial automation. Our panels are built with precision, incorporating top-tier PLCs (Programmable Logic Controllers), HMI interfaces, and robust electrical components to ensure seamless operation in demanding environments. From motor control and process automation to SCADA integration, our custom-engineered panels enhance efficiency, safety, and productivity. With rigorous testing, compliance to industry standards, and a commitment to innovation, we deliver scalable solutions for manufacturing, energy, water treatment, and beyond. Partner with us for durable, future-ready control systems that keep your operations running smoothly.

Optimized & Industry-ready Solutions

SCADA Syatems

As a trusted SCADA system integrator, we deliver end-to-end automation solutions that empower industries to monitor, control, and optimize their operations with precision. Our expertise spans designing, deploying, and integrating advanced “Supervisory Control and Data Acquisition (SCADA) systems“, tailored to meet the unique demands of water treatment, energy, manufacturing, and infrastructure sectors. Leveraging cutting-edge technologies—such as real-time data visualization, IoT connectivity, and predictive analytics—we enhance operational efficiency, reduce downtime, and ensure regulatory compliance. From PLC/RTU integration to cloud-based SCADA platforms and cybersecurity hardening, our certified team provides scalable, future-ready solutions. Partner with us to transform raw data into actionable insights and achieve seamless, intelligent automation across your enterprise.

Our Innovations

Industry Focused Products!

Motor Control Panels

As a premier LT Panel (Low Tension Panel) manufacturer, we specialize in designing and producing robust, high-performance electrical distribution solutions for industrial, commercial, and infrastructure applications. Our LT Panels are engineered for reliability, safety, and efficiency, ensuring seamless power distribution, motor control, and circuit protection. Built with top-grade components—such as MCCBs, contactors, and relays, our panels comply with global safety standards, offering customized configurations for HVAC systems, water treatment plants, manufacturing units, and more. With rigorous testing, energy-efficient designs, and a focus on durability.

Solar Structure

We provide high-strength, corrosion-resistant mounting solutions designed to withstand harsh environmental conditions while ensuring long-term durability for solar power plants. Our structures are fabricated using premium-grade steel and undergo *hot-dip galvanization* for superior rust protection, extending their lifespan even in coastal or high-humidity regions. Engineered for precision, our solar mounting structures support both rooftop and ground-mounted PV installations, offering customizable designs for optimal tilt, wind resistance, and easy installation.

s

C

Need Help with Easier Industrial Solutions? We Are Experts!

Click here to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.